Christie Projector Repair — Lamp, Laser Phosphor & RGB Pure‑Laser Specialists

We diagnose, repair and re‑certify Christie projectors from compact 1DLP to flagship 3DLP and RGB pure‑laser platforms. From lamp strike faults and colour wheel sync, to laser module derating, lens motor errors, PSU failures and precision colour calibration — our workshop restores performance to factory spec and backs it with a written engineering report.

Bench Diagnostics

Lens Service

Laser Module Inspection

Engineering‑first Christie repairs with fast diagnostics, parts in stock and accountable reporting

Full‑stack capability

We service 1DLP and 3DLP Christie platforms across lamp, laser phosphor and RGB pure‑laser. We troubleshoot power (PSU/ballast/laser drivers), video processing (mainboard, input board, HDBaseT), thermal (fans, NTCs, heatpipes), and optical (DMDs, prisms, light tunnels, phosphor wheels) end‑to‑end.

Rapid triage & reporting

Most units receive a same‑week diagnostic. You get a written engineering report covering root cause, parts list, labour steps and preventive recommendations — useful for insurers, venue owners and hire companies.

Calibration & matching

After repair, we calibrate brightness, white point and colour primaries. For multi‑projector arrays we match gamma, uniformity and geometry for clean blends and immersive canvases.

Christie models we repair — from boardrooms to domes and touring arenas

1DLP families

- GS Series — e.g., DWU880‑GS, DWU1400‑GS, DWU1100‑GS (laser phosphor 1DLP)

- HS Series — e.g., DWU900‑HS, DWU1080‑HS, DWU1600‑HS (1DLP high brightness laser)

- Captiva Series — ultra‑short‑throw models (e.g., DHD410S)

- LHD/LWU/LX Series — lamp‑based 1DLP models for corporate/education

- Roadster / Roadie (1DLP variants) — staging‑oriented single‑chip platforms

Typical issues: colour wheel sync/noise (where fitted), lamp strike failures (lamp models), laser derating, light tunnel collapse, DMD stuck mirrors/white dots, fan/thermal faults, PSU instability, input board failures, HDBaseT reception issues.

3DLP & flagship platforms

- M‑Series — including legacy Xenon units and the newer M 4K25 RGB

- Boxer Series — high‑output 3DLP for events/touring

- Crimson Series — ruggedised 3DLP laser for fixed/creative installs

- Griffyn Series — 3DLP RGB pure‑laser (e.g., Griffyn 4K32‑RGB)

- Mirage — advanced 3D/visualisation 3DLP platforms

Typical issues: laser PSU/driver faults, laser safety interlocks, prism contamination, DMD/formatter board issues, lens motor/encoder errors, network & control board faults, colour uniformity drift, cooling loop service.

Christie projection technologies and how we approach each in service

Lamp‑based Christie (UHP/Xenon): Many earlier LW/LHD/LWU and staging units rely on high‑pressure lamps. Common failure points include the lamp itself (end‑of‑life, arc instability), the ballast/ignitor (inrush components, IGBTs, HV cabling), and thermal controls (clogged filters, worn blowers, fouled heat‑exchangers). We triage by verifying lamp hours vs. real arc characteristics, checking strike voltage and regulation, measuring ripple on the ballast DC bus, and confirming safety interlocks (housing, door, airflow) to resolve intermittent no‑strike issues. Optically, dust ingress and old thermal paste around critical junctions can create local hotspots and colour non‑uniformity; we clean, reseat, and re‑align mirrors, integrators and the prism if necessary.

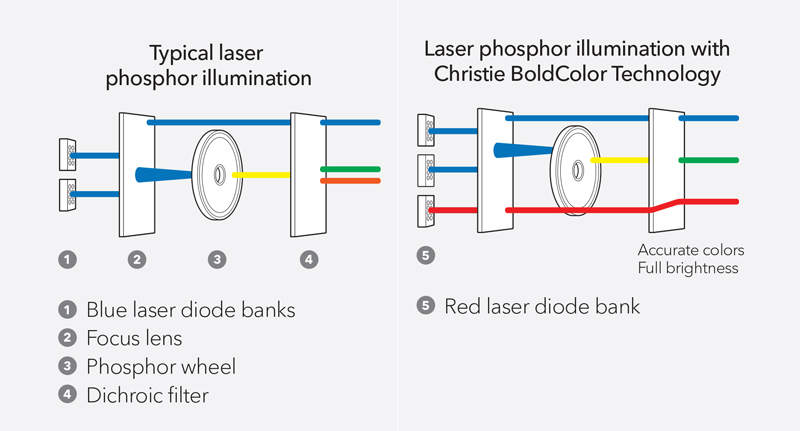

Laser phosphor (GS/HS/Crimson 1DLP & 3DLP): Laser phosphor modules use blue laser diodes driving a phosphor wheel. Over time, diode arrays can derate and wheel coatings can discolour from heat. We evaluate diode drive currents vs. expected luminance, examine phosphor wheel bearings and spectral output, and audit the cooling loop — fans, blowers, heatpipes, and NTCs — to correct dimming or colour shift. If brightness and colour cannot be recovered by optics cleaning and calibration alone, we replace worn modules or drivers, clear laser safety faults, and reset brightness baselines to match venue requirements.

RGB pure‑laser (Griffyn/M 4K25 RGB): These premium Christie platforms provide wide colour gamuts without a phosphor wheel. Faults tend to be in laser PSU stages, drivers, interlocks, or thermal paths around RGB arrays. We monitor per‑channel current, evaluate uniformity and convergence, and recalibrate white point to your content pipeline (e.g., Rec.709, DCI‑P3). After service, we run extended thermal soaks and stability plots to ensure output stays stable through long show windows.

1DLP vs. 3DLP optical paths: 1DLP units (especially lamp‑based) may include a colour wheel and light tunnel. Collapsed light tunnels cause severe brightness/geometry artefacts; we rebuild or replace. 3DLP uses three DMDs with a dichroic prism; contamination or misalignment can create colour fringes and non‑uniformity — we handle cleaning under controlled conditions, observing ESD and alignment protocols.

Electronics & I/O: Christie mainboards and input boards (HDMI/DisplayPort/3G‑SDI/HDBaseT) can fail due to ESD, heat, or connector wear. We reflow or replace BGA components where economically viable, and we stock replacement boards for fast swaps. We also validate control (RS‑232, TCP/IP, Christie command sets) so your automation resumes without reprogramming hassles.

Firmware & colour science: After hardware repair, we update firmware where appropriate, then calibrate brightness, gamma, greyscale and colour primaries. For multi‑unit arrays we match units for blends and warps, documenting target nits/lumens, white point (e.g., 6500K), and delta‑E across screen zones so you can evidence quality to clients.

Common symptoms we fix — and what typically causes them

Lamp won’t strike / shuts down

Usually ballast/ignitor aging, HV cabling leakage, lamp at end‑of‑life, or safety interlock/airflow faults. We check strike voltages, arc stability and replace suspect components.

Dim image / colour shift

Laser derating, phosphor wheel wear, dusty optics, or lamp decay. We measure brightness per channel, clean & reseal optics, replace worn modules, and recalibrate colour.

White dots or lines on image

DMD stuck mirrors or formatter issues on 1DLP; on 3DLP, could be a single channel DMD/formatter. We test formatter clocks, replace DMDs and re‑align optics as needed.

Over‑temperature warnings

Clogged filters, failing blowers, dried thermal interface materials, or sensor failures. We deep‑clean, replace fans, renew TIMs and validate thermal control loops.

Lens shift/zoom/focus errors

Encoder drift, motor wear, or cabling. We service the lens carriage, reset limits, replace encoders/motors and re‑verify geometry.

No video / input board faults

Failed HDMI/DP/HDBaseT boards, ESD damage or BGA solder fatigue. We swap input boards, repair where viable, and test at native timings.

Our Christie repair workflow — transparent, documented, accountable

- Collection & intake: We arrange insured courier collection across the UK, Ireland and Europe, or accept drop‑off at our Doncaster service centre. We log serials and accessories.

- Initial power‑on & safety checks: Earth continuity, insulation resistance, and interlocks are verified before extended diagnostics.

- Thermal & optical baseline: We capture brightness/colour baselines, thermal behaviour, fan curves and error logs to pinpoint modules.

- Board‑level diagnosis: PSU rails, ballast/laser drivers, formatter boards, sensors and input stages are instrumented to locate the fault domain.

- Quotation & authorisation: You receive a parts/labour quote with options (OEM vs. equivalent where available) and lead times.

- Repair & parts replacement: We replace or rework the failing modules; optics are cleaned, sealed and aligned; firmware updated where beneficial.

- Calibration & soak: After the fix, we run extended thermal soaks and recalibrate brightness, white point, gamma and uniformity.

- QC & engineering report: You receive a written report and QC sheet with measured performance before return shipping.

Christie status lights, warnings and typical error messages

Exact messages vary by model and firmware. The list below covers typical warnings and what we usually find behind them. If your projector shows a different message, send us a photo — we’ll advise.

| Indicator / Message | What it usually means |

|---|---|

| Lamp Strike Failed / Lamp LED blinking | End‑of‑life lamp, ballast/ignitor aging, HV cable tracking, door/cover interlock, or airflow not proven. |

| Laser Module Error / Laser disabled | Laser PSU/driver failure, diode string imbalance, over‑temp, or safety interlock open. |

| Colour Wheel Fault (1DLP models only) | Hall sensor loss, motor driver fault, seized bearings, or cracked wheel. |

| Over Temperature / Fan Error | Dust‑clogged filters, failing blowers, sensor faults, dried TIMs or blocked ducts. |

| Input Board Not Detected | HDMI/DP/HDBaseT card failure or backplane connector issues. |

| Lens Motor Error | Shift/zoom/focus motor or encoder fault; obstruction in lens carriage. |

Parts & capabilities — what we stock and how we shorten downtime

Critical spares on hand

Lamps & ballasts, phosphor wheels, fans & blowers, selected laser driver modules, DMDs (1DLP/3DLP), formatter boards, input cards, sensors, encoder/motor sets, key cabling looms.

Specialist tooling

Optical cleaning kit & ESD benches, thermal imaging, high‑voltage probes, precision torque tools for lens carriers, spectro‑radiometry for colour calibration, and multi‑unit blend rigs.

Documentation & sign‑off

Every job ships with an engineering report, QC checklist and calibration sheet so venues and insurers have a traceable record.

Preventive maintenance for Christie fleets — protect brightness, colour and uptime

Quarterly air path care: Christie platforms rely on predictable airflow. Filters clog, ducts accumulate dust, and blower RPM can drift with age. A quarterly clean prevents thermal throttling that silently robs brightness and shortens component life. We log RPM, current draw and thermals to anticipate failures.

Optics hygiene: Dust on integrators, prisms and relay optics reduces contrast and creates colour non‑uniformity. We use lint‑free techniques and approved solvents, then reseal carefully to limit future ingress. In harsher venues (staging, dusty halls), we suggest six‑monthly optics checks.

Laser health checks: For laser phosphor and RGB units, we chart output vs. drive current and temperature. If a channel is rising in current yet brightness is flattening, it indicates derating. Early intervention (driver replacement, module swap, or thermal remediation) prevents on‑show failures.

Lamp lifecycle: For lamp models, don’t just follow hour counters. We monitor arc stability, strike voltage and on/off cycles. Poor mains quality and short cycles damage lamps and ballasts; a stabiliser or operational tweak can double useful life.

Firmware & colour consistency: Keeping to a standard firmware and colour target across a fleet simplifies show prep. We maintain a golden profile by model so replacements drop into blends with minimal tweaking.

Who we support — from education halls to dome theatres and touring rigs

Education & Corporate: GS/HS and LW/LHD/LWU families dominate teaching spaces and boardrooms. We prioritise quick turnarounds, predictable budgets and simple collection/return logistics.

Museums & Attractions: Long‑hour duty cycles and fine edge‑blends demand stability. We rebuild cooling pathways, match colours between units and document settings so future swaps remain seamless.

Rental & Staging: For Boxers, Crimson and Griffyn fleets, time is money. We carry critical spares and can prep show‑ready spares while your unit is in service, keeping rig schedules intact.

Visualisation & Simulation: Mirage and 3D/VR environments need precise geometry and colour. We capture full‑field uniformity maps and deliver repeatable profiles for your content pipeline.

Recent repair stories (anonymised)

Crimson laser derating in a gallery

Symptom: noticeable dimming and green shift after months of continuous use. Root cause: restricted airflow around the phosphor wheel housing raised temps, accelerating coating wear. Fix: restore duct integrity, replace wheel, recalibrate colour; the gallery recovered uniform brightness and neutral whites.

GS 1DLP white‑dot outbreak

Symptom: peppered white dots across the image mid‑lecture. Root cause: DMD stuck mirrors. Fix: replace DMD and reseat formatter board; install new filters to improve dust control; unit passed 72‑hour soak with clean image.

Griffyn RGB colour mismatch in blend

Symptom: one unit in a three‑wide blend looked warm. Root cause: drifted white point after a driver replacement elsewhere. Fix: recalibrate RGB currents, align primaries, and verify gamma; blend became seamless.

UK, Ireland & Europe — collection & return or on‑site by arrangement

- Collection & return: Insured courier collection, pro‑packing and return. Pallet options for large 3DLP rigs.

- On‑site support: For critical venues we can attend on site to triage and stabilise while the main repair proceeds in‑house.

- Documentation: Engineering report, QC sheet and calibration notes accompany every serviced unit.

Frequently asked questions

Do you work on legacy lamp models? Yes. We hold stock of common lamps and select ballasts, and we can refurbish compatible PSUs/ignitors. If OEM parts are obsolete, we evaluate safe equivalents.

How long does diagnosis take? Typical triage is 3–5 working days from arrival. If we identify a known failure pattern early, we may fast‑track parts ordering with your approval.

Can you match projectors for a blend? Yes, including brightness balancing, white point, gamma and edge geometry so multi‑projector canvases look seamless.

Do you visit sites? We prefer in‑house repairs for full tooling access, but can attend sites when downtime is critical or access is constrained.

What’s the warranty? 90–180 days depending on parts class and usage profile. We also offer fleet cover for rental companies.

Will you provide a report? Yes — an engineering report accompanies every paid diagnostic or repair, suitable for insurers and venue stakeholders.

Do you repair lenses? We service lens carriages, motors and encoders, and clean front elements. Element‑level lens re‑grinding is out of scope; we source replacements if required.

Can you copy my existing configuration? We back up settings where possible and can restore input timings, colour targets and geometry after repair.