Christie Projector Repair — Lamp, Laser Phosphor & RGB Specialists

We diagnose, repair and re‑certify Christie projectors from compact 1DLP to flagship 3DLP and RGB pure‑laser platforms. Whether you are facing lamp strike faults, laser derating, or colour drift, our workshop restores performance to factory specification. We don't just swap parts; we understand the physics of projection, providing deep component-level analysis backed by comprehensive engineering reports.

Precision Engineering for High-Value Projection

In an industry often driven by costly module replacements, Wells Electronics takes a different approach. We believe in forensic electronics—identifying the root cause of failure rather than just treating the symptom.

Many service centers will condemn a projector simply because a replacement mainboard exceeds the unit's economic value. We go deeper. By analyzing power rail stability, thermal signatures, and signal integrity at the component level, we can often repair high-value boards (such as laser drivers, ballasts, and formatters) that others would discard. This not only significantly reduces the repair cost but also drastically lowers electronic waste.

Our workshop is equipped with specialized diagnostics tools, including thermal imaging cameras to detect hotspots before they cause failure, high-bandwidth oscilloscopes to measure DC ripple on laser diode banks, and industrial spectroradiometers for precise colour calibration. We don't just return your projector working; we return it calibrated, stable, and ready for critical show environments.

Specialist Service Pathways

Select your technology platform to understand our specific diagnostic and repair capabilities. We support the full lifecycle of Christie equipment.

lightbulb Lamp (UHP/Xenon)

For legacy LW/LHD/LWU and Roadster/Roadie models. We address intermittent strike failures, ballast ripple issues, and aging optical coatings. Our service includes comprehensive cooling path rebuilds to extend lamp life and reduce fan noise.

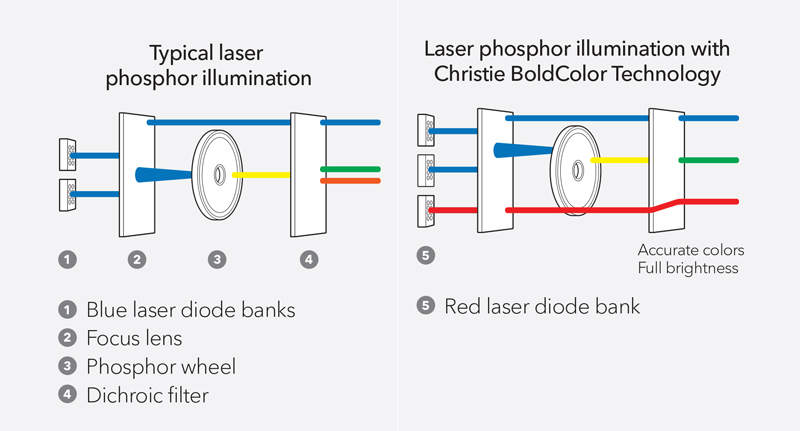

settings_input_component Laser (Phosphor & RGB)

Covering GS/HS, Crimson, and Griffyn RGB series. We service laser drivers, replace phosphor wheels, and calibrate RGB arrays. Critical attention is paid to safety interlocks, thermal derating, and white-point balance.

warning Error Codes

System status lights and error logs tell a story. Before shipping, consult our triage guide for thermal warnings, fan locks, and power rail faults. Some issues can be resolved on-site without shipping.

The Christie Ecosystem: Models We Maintain

Our workshop maintains spares and technical schematics for the majority of the Christie fleet, ensuring rapid turnaround for both legacy and current-generation units.

videocam 1DLP Laser Phosphor

GS, HS, Captiva Series.

Common in corporate/uni. We resolve colour wheel bearing noise, phosphor degradation, and "system error" shutdowns caused by driver faults.

theaters 3DLP Xenon

M-Series, J-Series, Roadster.

The workhorses of rental. We handle ballast rebuilds, high-voltage ignition failures, and deep optical cleaning to restore contrast.

palette 3DLP RGB Laser

Griffyn, M 4K25 RGB.

Precision instruments. We focus on RGB laser array balancing, complex cooling loops, and maintaining Rec.2020 colour compliance.

grid_view LCD / Legacy

LW, LWU, LHD Series.

We support older inorganic LCD panels, replacing polarizers and cleaning prisms to remove yellow/magenta discolouration.

Anatomy of a Failure: What We Fix

Projectors fail for physical reasons. We address the root causes found in high-performance AV environments.

- Thermal Throttling: Dust accumulation on heatsinks forces fans to run at 100%, eventually triggering safety shutdowns. We ultrasonic clean heatsinks and replace thermal interface materials (TIM).

- Optical Degradation: "Hazy" or yellowed images are often caused by outgassing on internal lenses or polarized filters. We meticulously clean or replace optical elements.

- Power Regulation: Flickering images often stem from DC ripple on the ballast or laser driver rails. We re-cap and stabilize power distribution boards.

- Mechanical Wear: Grinding noises usually indicate failed bearings in colour wheels or blower fans. We use high-speed, precision bearings for replacements.

Why Leading Venues Trust Us

description Traceability

Every job generates a written Engineering Report detailing the exact fault, components replaced, and post-repair test data. You have a full audit trail for insurance and compliance.

science Calibration

We don't guess colour. We use industry-standard spectroradiometers to align white point and colour gamut (Rec.709, DCI-P3) to ensure your multi-projector blends match perfectly.

security Warranty

We stand by our engineering. All repairs are backed by a comprehensive warranty on both parts and labour, giving you peace of mind for the next season of events.

Don't Scrap It — Service It

High-end Christie projectors are built to last decades, not years. Proper maintenance and repair is the most sustainable choice for your budget and the environment.

recycling WEEE & Carbon Footprint

Manufacturing a 50kg 3DLP projector generates a massive carbon footprint. By repairing electronics at the component level rather than discarding whole units, we significantly reduce e-waste. Extending the life of your asset by just 3 years can reduce its annualized carbon impact by over 40%.

savings ROI Maximization

A preventative service costing a fraction of a new unit can bridge the gap between "broken" and another 5 years of revenue generation. For rental companies, this directly impacts the bottom line, keeping assets earning without capital expenditure.

Secure Collection Across UK, Ireland & Europe

We understand that shipping a £20,000 projector requires care. Our logistics team handles the entire process.

- Insured Courier: We use dedicated couriers for sensitive electronics, offering insurance up to the full replacement value of the unit.

- Flight Case Handling: We are experienced in handling large touring flight cases. No need to unbox; just label the case, and we handle the palletization.

- Packaging Assistance: If you don't have original packaging, we can provide guidance or ship secure crates to your location before collection to ensure transit safety.

Frequently Asked Questions

Common queries regarding our Christie repair services.

What is your typical turnaround time?

Our standard turnaround for diagnostics is 3-5 working days from receipt. Repairs typically take another 3-7 days depending on parts availability. For urgent live events, we offer an expedited "Jump the Queue" service to get your unit back on the road immediately.

Do you repair units that are out of warranty?

Yes, the vast majority of our work is on out-of-warranty units. As an independent specialist, we can often repair units that the manufacturer has deemed "End of Life" (EOL) by sourcing components or repairing boards that are no longer sold new.

Can you match colours for a blended projection stack?

Absolutely. If you send us the reference unit (or target coordinates), we can calibrate the repaired unit to match. We use professional colorimeters to adjust the RGB primaries and white point, ensuring the repaired unit slots seamlessly back into your blend.

Do you offer on-site repairs?

For diagnosis and simple module swaps (lamps, filters, fans), we can attend on-site. However, for deep electronics repair, optical alignment, or laser calibration, we strongly recommend bench service where we have access to clean-room environments and precision test equipment.

What happens if the projector is unrepairable?

In the rare event a unit is beyond economical repair (BER), we offer a transparent breakdown of why. We can then either return the unit, environmentally recycle it for you (WEEE compliant), or offer to purchase it for parts to salvage useful components for other repairs.

Bench Diagnostics

Lens Service

Laser Module Inspection

Wells Electronics Ltd — The Projector Repair Specialists

Unit 9 West Moor Park, Yorkshire Way, Doncaster, DN3 3GW • +44 333 006 4327